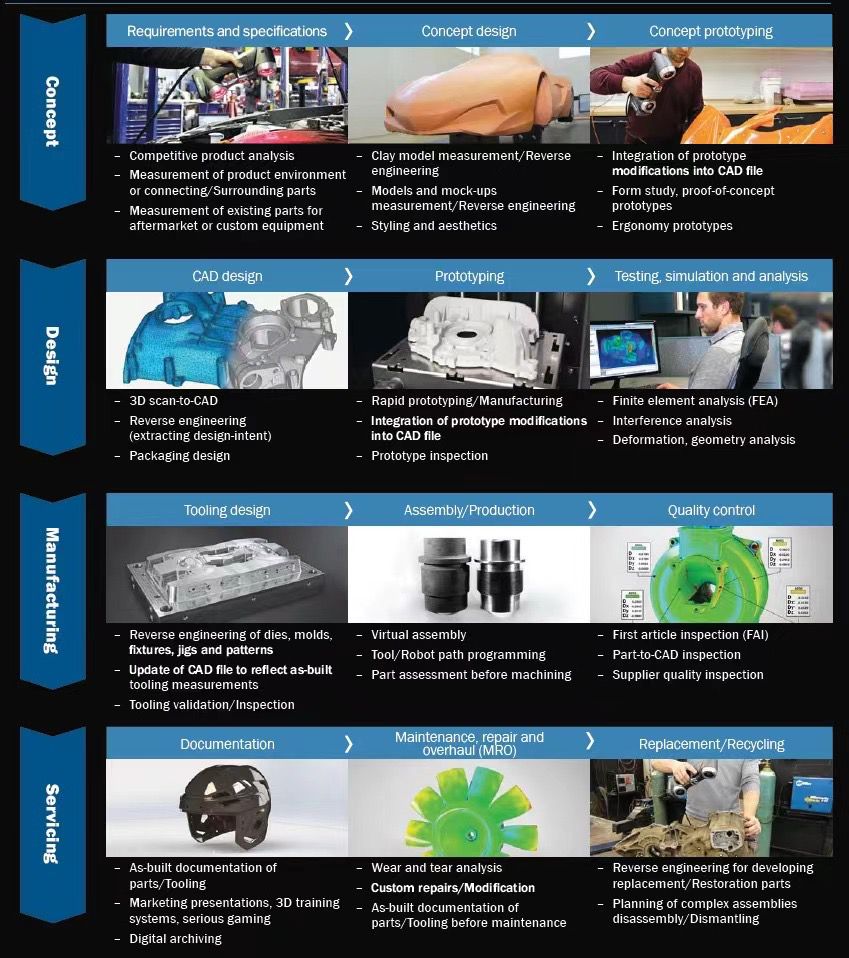

3D Laser Scanning Service

Applications

-

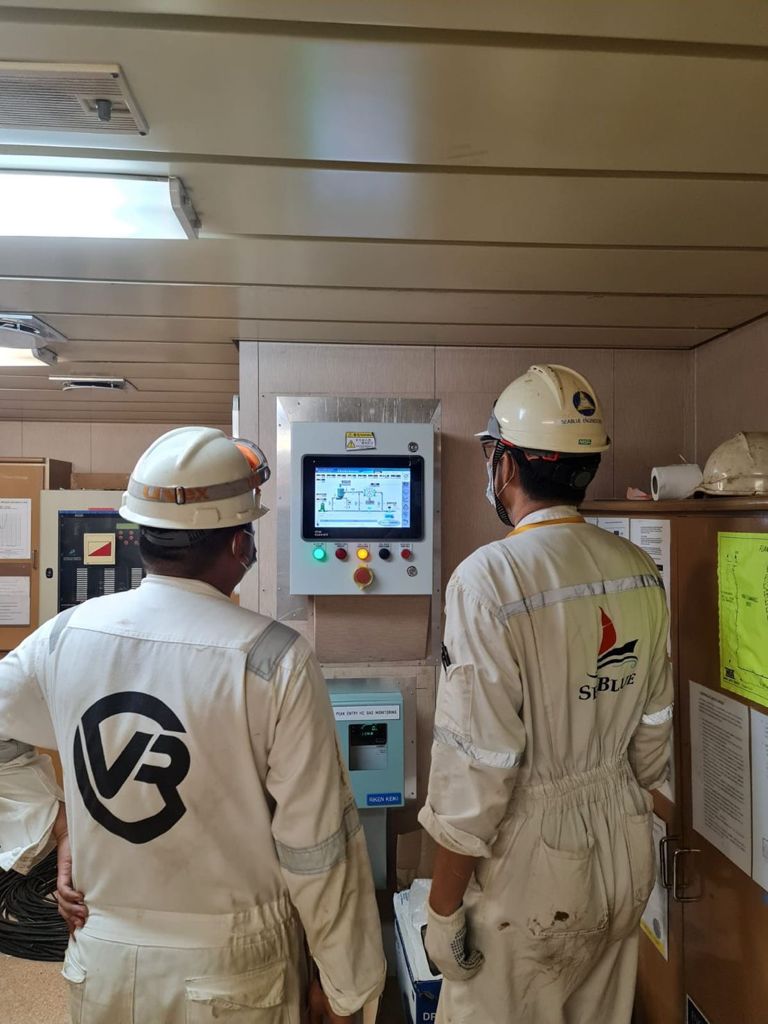

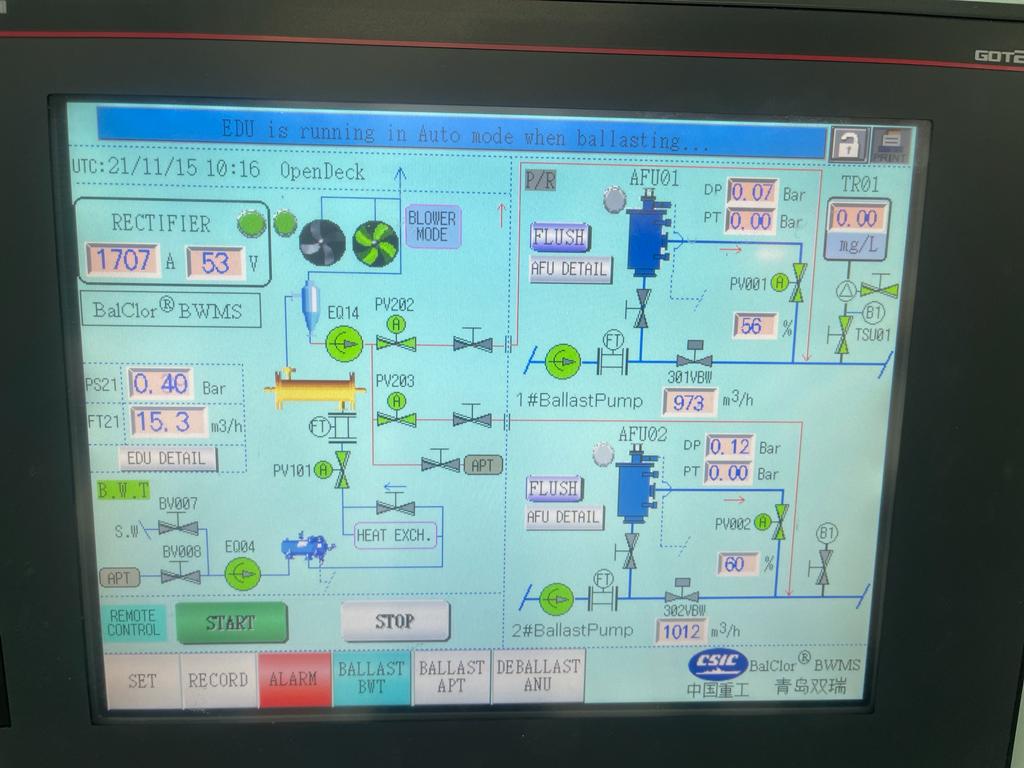

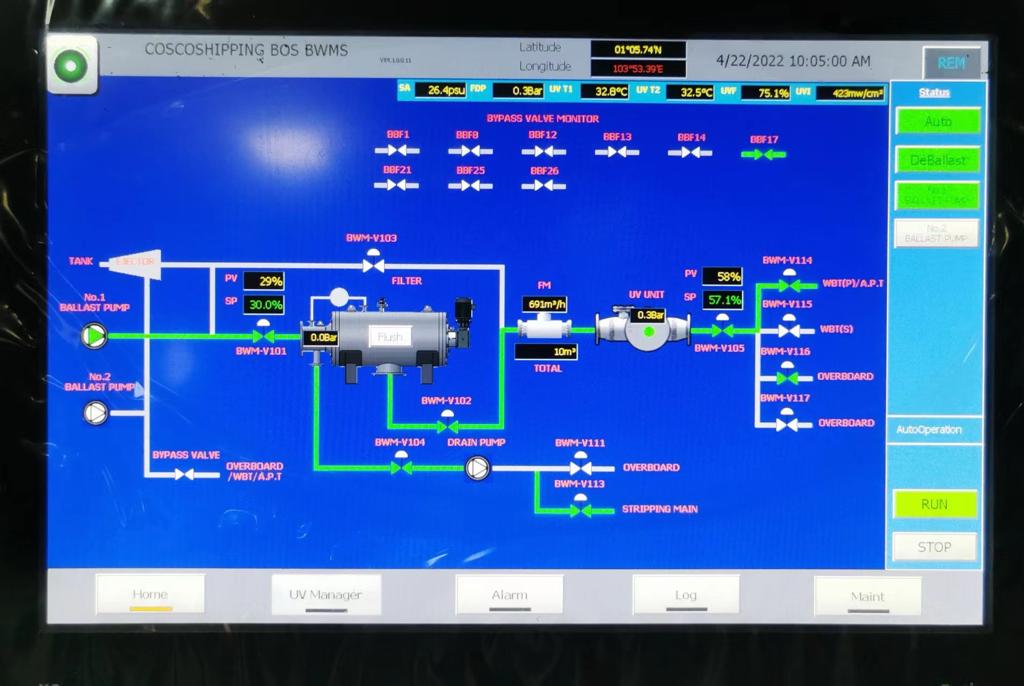

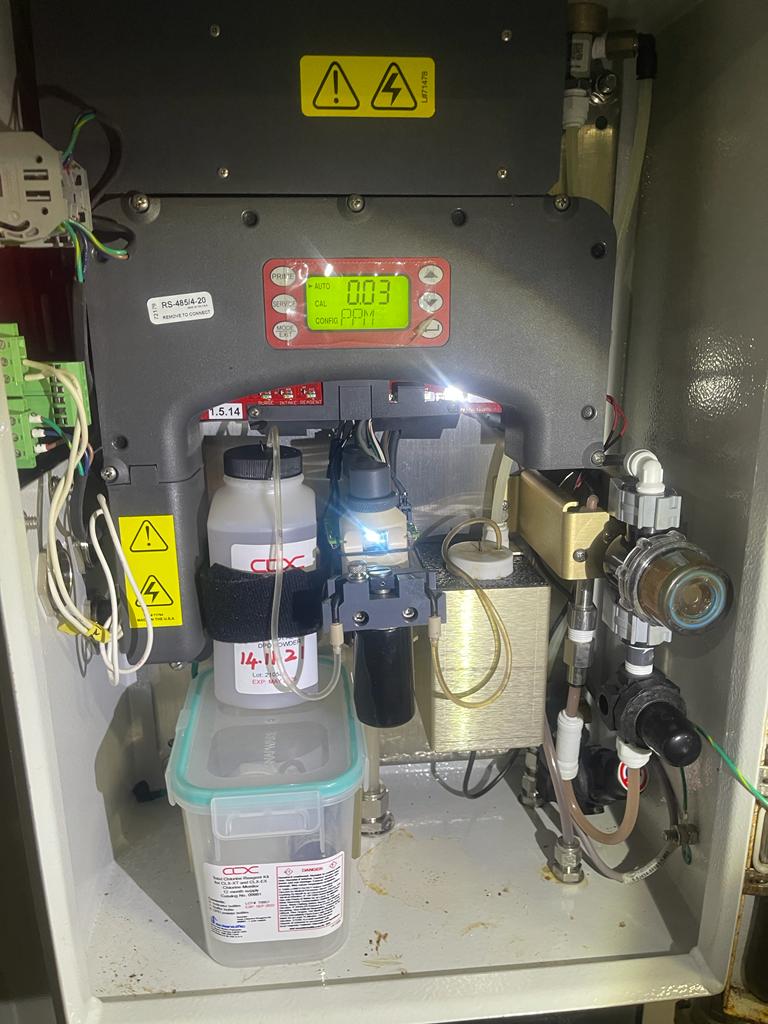

Retrofit Engineering: Scanning ships to plan installations for Ballast Water Treatment Systems (BWTS), Exhaust Gas Cleaning Systems (EGCS), and more, ensuring perfect fit.

-

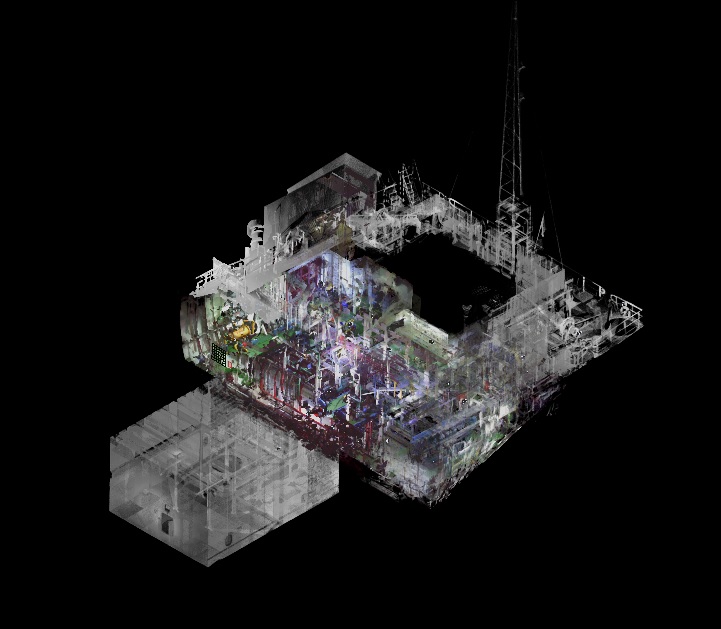

Digital Twins: Creating detailed 3D models (point clouds) of existing vessels for comprehensive digital records.

-

Clash Detection: Identifying conflicts between new equipment and existing structures before installation.

-

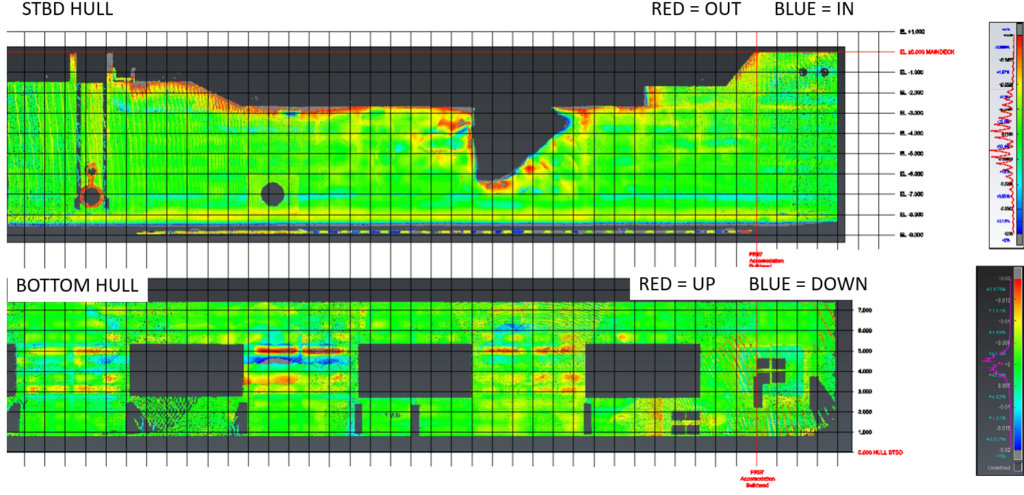

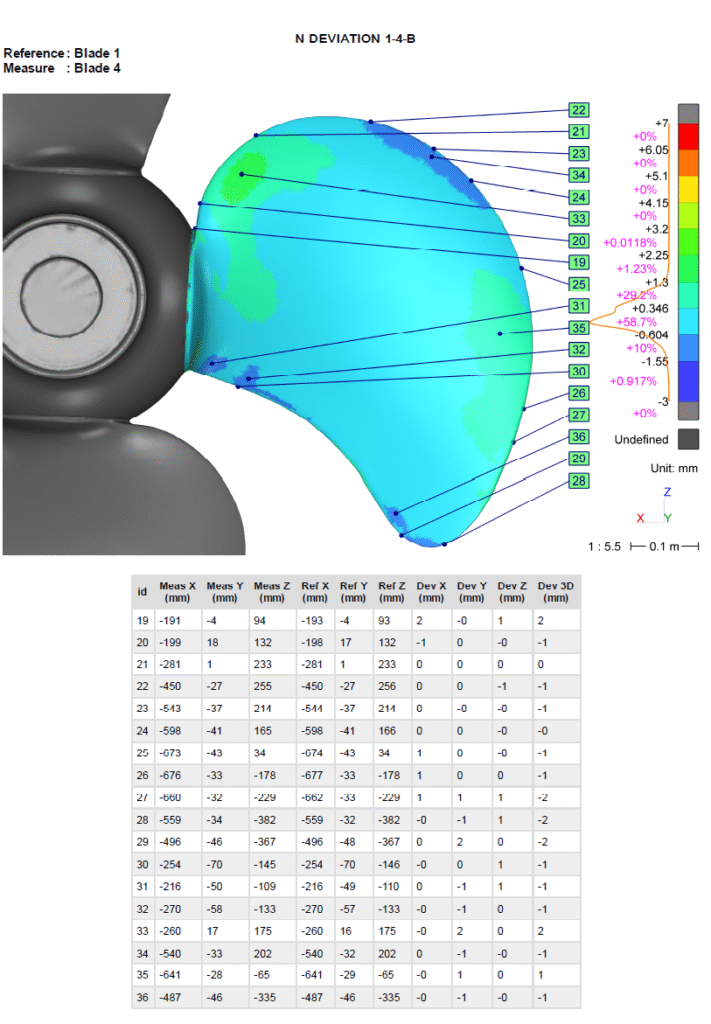

Hull Surveys: Checking for outside hull surface deformations.

-

Tank Volume Calculations: Accurately measuring volumes for various needs.

-

Reverse Engineering: Creating digital models from physical asset like ship, oil plat form, power plant and etc.

Benefits of SeaBlue’s 3D Laser Scanning

-

Accuracy: Eliminates manual measurement errors, providing high-precision data.

-

Efficiency: Reduces engineering time and site visits by allowing design work in the office.

-

Cost Savings: Allows for pre-fabrication of components (like pipe spools) and reduces field welds, lowering shipyard costs.

-

Operational Continuity: Scanning can often happen while ships are in operation, minimizing downtime.

How it Works

-

Laser scanners capture millions of precise data points (a point cloud) of the physical space.

-

This data forms a highly detailed digital image, or “digital twin,” of the vessel’s interior or exterior.

-

Engineers use this data in 2D/3D software to design, plan, and verify installations, ensuring optimal performance and compliance